Strain rate-dependent tension-compression asymmetry in cast Mg-Gd-Y Alloy: Insights into slip and twinning mechanisms. (pdf, doi)

J. Mater. Sci. Technol. 219, 134–146 (2025). by J. L. Li et al.

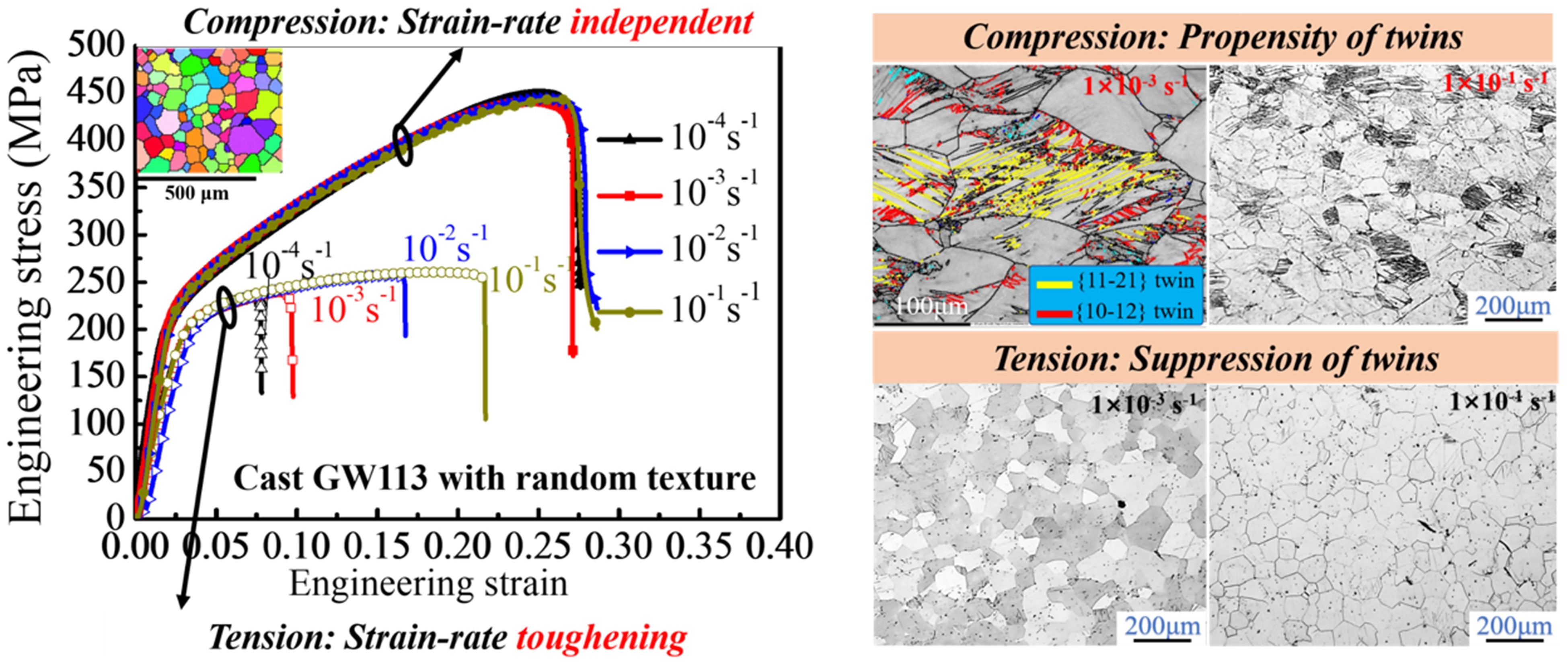

The cast GW113 alloy exhibits unusual tension-compression asymmetry, showing strain rate toughening in tension but strain rate independence in compression. Pyramidal slip significantly contributes to strain rate toughening under tension but plays a minimal role in compression. The alloy displays rare twinning under tension but prominent twinning under compression, due to rare earth element effects. The impact of compression stress state on promoting twinning is demonstrated.

Mitigating surface notches for enhanced fatigue performance of metallic gyroid structures via contour scanning. (pdf, doi)

Int. J. Mech. Sci. 286, 109913 (2025). by L. M. Huang et al.

This study investigates the impact of contour scanning, a remelting technique in selective laser melting (SLM), on the fatigue behavior of 316L gyroid lattice structures. The contour scanning significantly enhances high-cycle fatigue endurance by improving surface smoothness and reducing defects such as microcracks and notches. Cyclic ratcheting is identified as the dominant fatigue mechanism in both contour-scanned and non-scanned gyroid structures. Furthermore, fatigue life predictions using finite element analysis, informed by experimental data and Basquin's equation, align closely with experimental results.

Equilibrium analysis of surface-constrained elastic rods: Unveiling contact and internal forces through local geometry. (pdf, doi)

J. Mech. Phys. Solids 187, 105635 (2024). by M. Wang and X. Yi

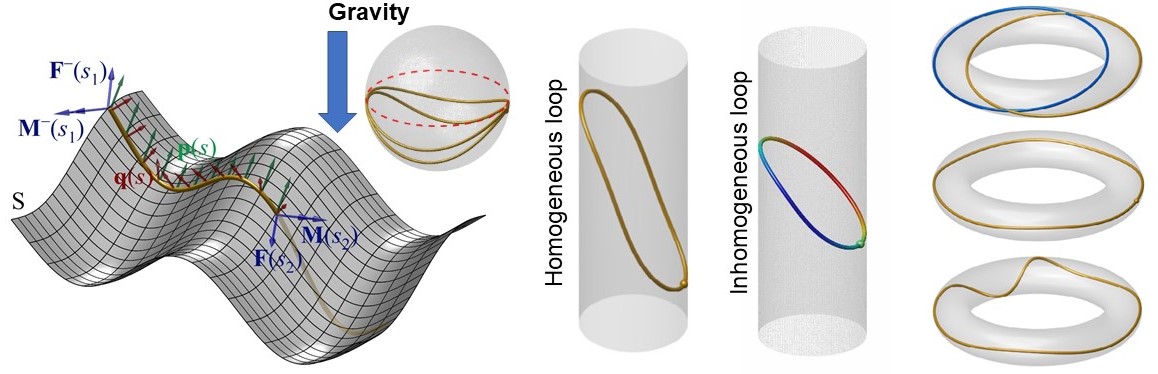

A theoretical framework is developed to characterize the equilibrium state of a thin elastic rod constrained on an oriented surface. It accommodates both homogeneous and inhomogeneous rods and includes the effects of a conservative force field. By projecting internal forces and moments onto the Frenet–Serret frame, analytical expressions for contact and tangential forces are derived, addressing prior challenges with indeterminate parameters. Examples on spherical, cylindrical, and toroidal surfaces illustrate how geometry influences rod configurations and forces.

Deformation, shape transformations, and stability of elastic rod loops within spherical confinement. (pdf, doi)

J. Mech. Phys. Solids 191, 105771 (2024). by M. Wang et al.

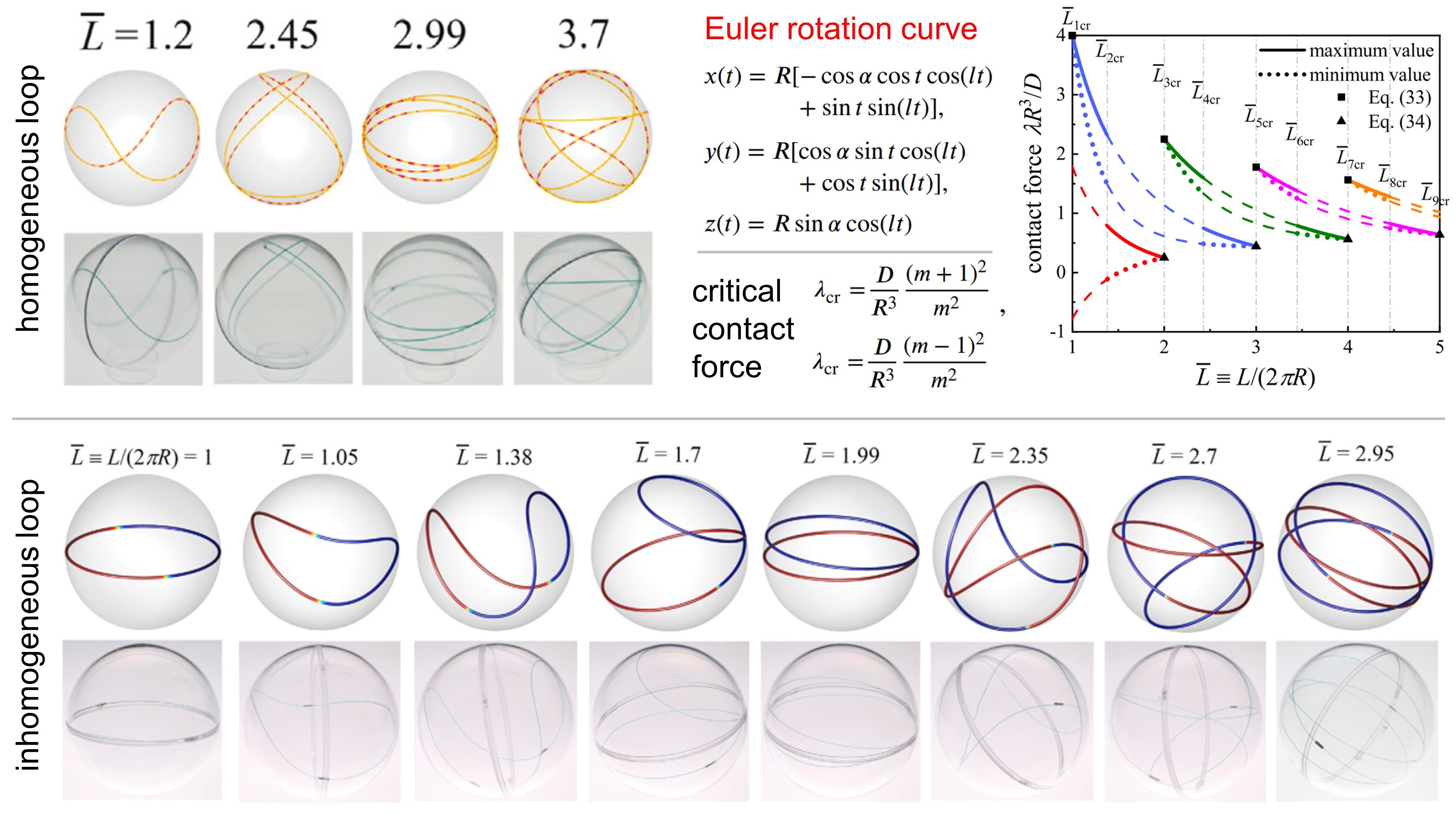

Surface-constrained homogeneous rod loops exhibit various stable and metastable configurations, including circles, saddles, and figure-eights. Using the proposed Euler rotation curve approximation, concise predictive solutions for rod configurations are derived. Analytical solutions for internal and contact forces are achieved. For inhomogeneous rods, stiffer segments align closer to the great circle, while softer segments deform more.

Stretching transition of vesicles with confined filament loops: Morphological evolution with filament distortion and reorientation. (pdf, doi)

Giant 17, 100233 (2024). by C. Y. Zhang et al.

The stiffness and length of filament loops, combined with vesicle scenarios, play a crucial role in shaping system energy, axial forces, and morphological transformations. Under zero osmotic pressure, flexible filaments favor spherical vesicles, while stiffer filaments lead to oblate vesicles, both transitioning into rod-like forms during stretching, accompanied by filament elongation and a spring-softening response. In fixed-volume vesicles, stretching transforms prolate or oblate shapes into lemon- and eventually cherry-like morphologies with tubular protrusions. Filament loops exhibit distinct buckling or reorientation behaviors, with the system displaying spring-stiffening prior to protrusion formation.

Angle-dependent protrusion of cell membranes. (pdf, doi)

J. Mech. Phys. Solids 183, 105500 (2024). by H. Y. Tang et al.

Indentation of pore-spanning lipid membranes: Spring-stiffening or -softening responses and apparent stiffness prediction. (pdf, doi)

Extreme Mech. Lett. 57, 101917 (2022). by X. Y. Zhang et al.

Strength–ductility synergy in Mg-Gd-Y-Zr alloys via texture engineering in bi-directional forging. (pdf, doi)

J. Magnes. Alloys 12, 4709–4721 (2024). by J. L. Li et al.

We introduce a novel bi-directional forging process for efficiently and cost-effectively producing high-strength Mg-11Gd-3Y-0.5Zr alloy, surpassing conventional multi-directional forging. Following a total compressive strain of 1.83, the PED sample (with its axial direction aligned to the elongation direction) demonstrates significant enhancements in tensile strength and ductility, achieving an ultra-high yield strength after annealing. In the PED sample, texture reduces basal slip anisotropy and activates non-basal slip systems, particularly pyramidal <c + a> slip, improving strength, strain coordination, and ductility. Meanwhile, in the PFD sample (with its axial direction parallel to the forging direction), texture weakening offsets grain refinement, limiting property improvement.

Multiscale modeling of dislocation-mediated plasticity of refractory high entropy alloys. (pdf, doi)

J. Mech. Phys. Solids 187, 105635 (2024). by F. Zhao et al.

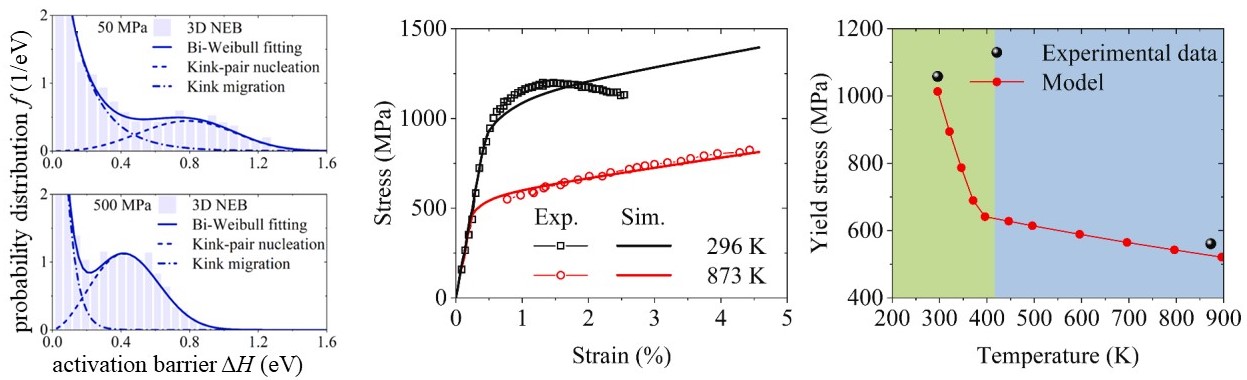

This study investigates screw dislocation glide and kink-pair nucleation in NbMoTaW, a typical refractory high entropy alloy (RHEA), with a multiscale framework applied to the uniaxial response across temperatures. Statistical analysis reveals two distinct mechanisms—kink-pair nucleation (rate-limiting) and kink migration—with a higher activation barrier for nucleation. A proposed stochastic line tension model aligns with NEB results, reducing computational cost. An atomistically-informed crystal plasticity framework is developed and accurately predicts RHEA yield strength and stress-strain behavior, advancing understanding of dislocation mechanics in random solution alloys.

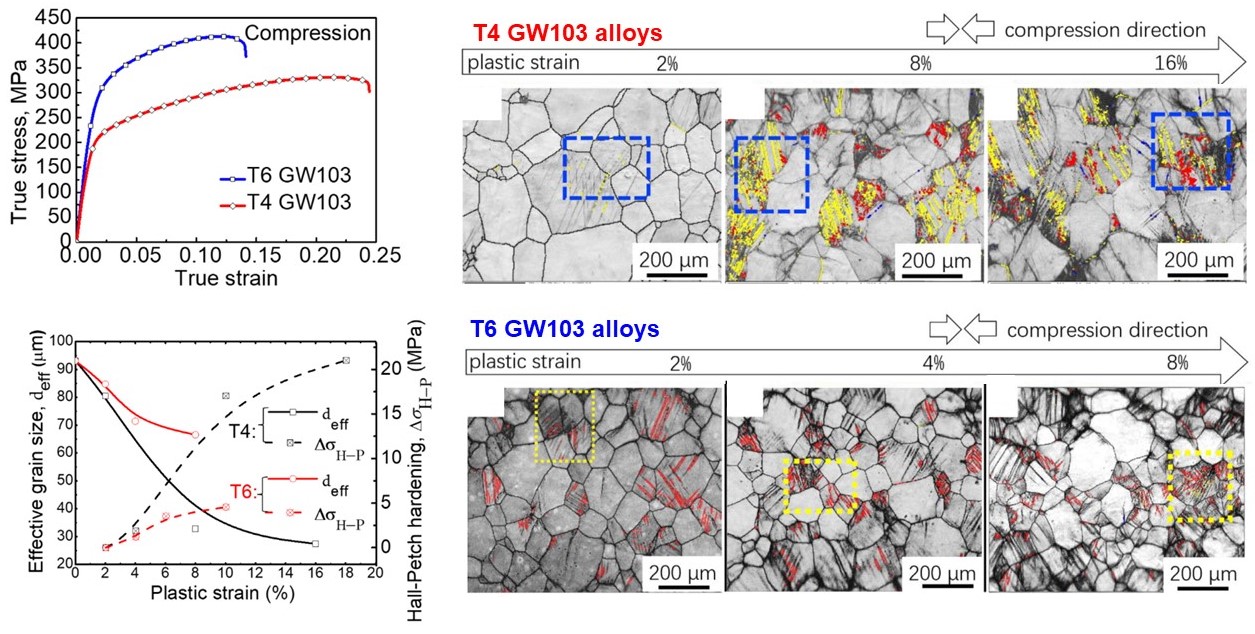

Twin evolution in cast Mg-Gd-Y alloys and its dependence on aging heat treatment. (pdf, doi)

J. Magnes. Alloys 11, 2285–2298 (2023). by L. J. Li et al.

This study investigates the effects of rare-earth (RE) elements and precipitates on twin evolution in cast Mg-10Gd-3Y-0.5Zr (GW103) alloys under room-temperature compression, comparing solid solution (T4) and aged (T6) states. Both {10–12} and {11–21} extension twins (ET1 and ET2) are observed, but their nucleation sequences differ: in the T4 state, ET2 precedes ET1 due to RE solutes inhibiting ET1 nucleation, while in the T6 state, reduced solute content after precipitation reverses the sequence. Extension twins primarily assist plastic deformation via non-Schmid effects.

Morphological transformations of vesicles with confined flexible filaments. (pdf, doi)

Proc. Natl. Acad. Sci. U. S. A. 120, e2300380120 (2023). by C. Shi et al.

Theoretical modeling and MD simulations reveal diverse morphologies in filament–vesicle systems, with phase diagrams linking shape transitions to filament stiffness and size. Open filaments induce complex vesicle shapes, including oblate, dumpling, pebble, droplet, and racket-like configurations, while closed loops transition to nonaxisymmetric shapes such as saddle, oval, and figure-eight forms. Energy analysis uncovers physical mechanisms driving these deformations. The results enhance our understanding of filament organization, cell shaping, and the design of artificial cells.

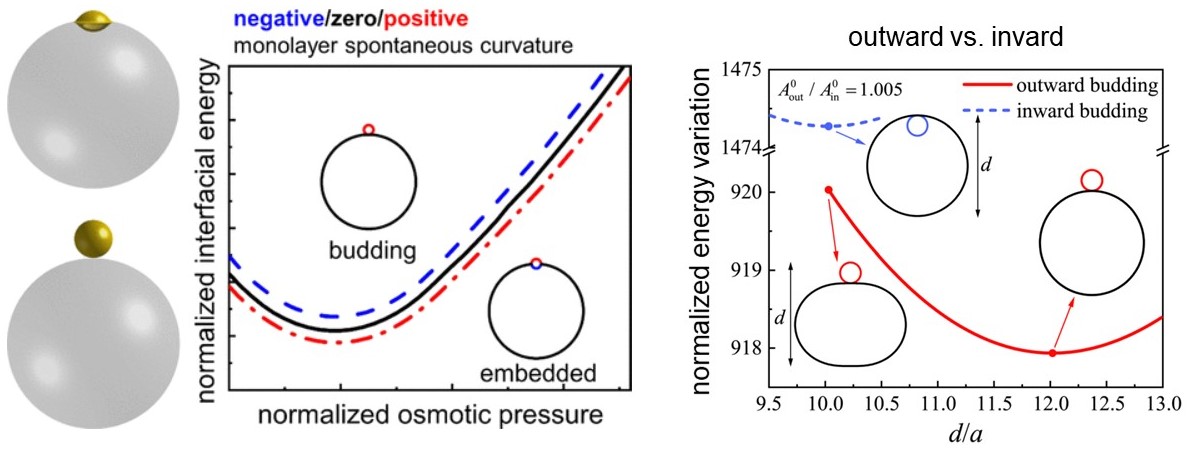

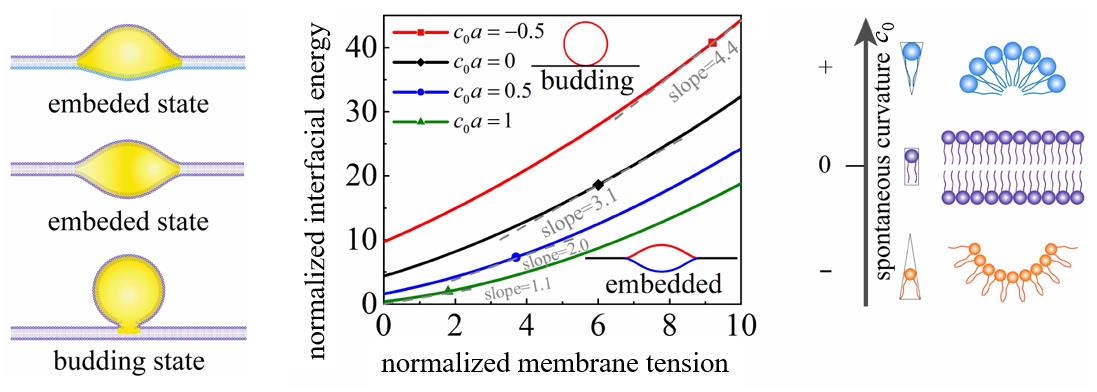

Area difference between monolayers facilitates budding of lipid droplets from vesicles. (pdf, doi)

Soft Matter 19, 7494–7501 (2023). by M. Wang and X. Yi

Bulging-to-budding transition of lipid droplets confined within vesicle membranes. (pdf, doi)

Langmuir 37, 12867–12873 (2021). by M. Wang and X. Yi

Our theoretical studies model the morphological evolution of lipid droplets (LDs) confined within vesicle membranes, focusing on bulging and budding behaviors. When the interfacial interaction strength or monolayer area difference exceeds critical thresholds, the LD transitions from an embedded lens-like shape to a spherical protrusion connected to the vesicle via a monolayer neck. Budding phase diagrams reveal that low osmotic pressure promotes budding, while high osmotic pressure inhibits it. For monolayer area differences, osmotic pressure facilitates budding at small differences but suppresses it at larger ones. Positive spontaneous curvature and lipid addition to the outer monolayer favor outward budding, whereas lipid depletion induces inward budding.

Nanoparticle elasticity regulates the formation of cell membrane-coated nanoparticles and their nano-bio interactions. (pdf, doi)

Proc. Natl. Acad. Sci. U. S. A. 120, e2214757120 (2023). by D. Zou et al.

We highlight the role of nanoparticle (NP) stiffness in regulating cell membrane-coated NP formation, protein profiles, and NP–cell interactions. Soft membrane-coated silica nanoparticles (MCSNs) form coatings with higher protein density (e.g., CXCR4, CD90), enhancing cancer cell uptake compared to hard MCSNs. In vitro models confirm the CXCR4/SDF-1 axis's role in improving cancer targeting through the endothelial barrier and ECM. These mesenchymal stem cell membrane-coated NPs, capable of carrying hydrophobic payloads, show potential for cancer treatment.

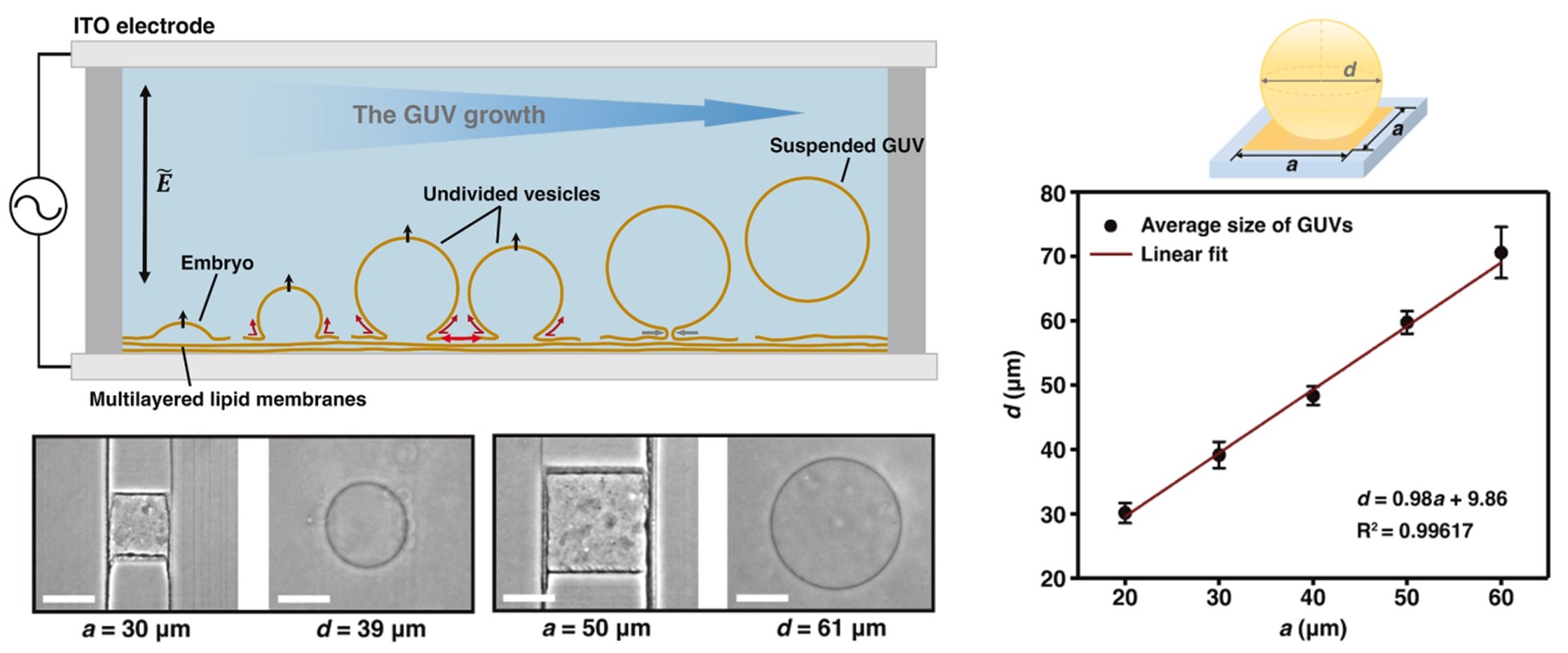

Membrane-tension-dominated growth mechanism and size modulation of giant unilamellar vesicles in electroformation. (pdf, doi)

J. Mech. Phys. Solids 170, 105120 (2023). by Z. H. Liang et al.

We develop a modified Helfrich model with dielectrophoretic stress to study GUV growth, revealing a membrane-tension-dominated mechanism that inhibits budding and induces growth instability. This mechanism is validated through electroformation experiments using flat-coated films with holes that reduce tension and uncouple GUV growth. Based on this, we propose a method to prepare size-controllable, detachable GUVs with high uniformity, meeting biophysical and biomedical needs.

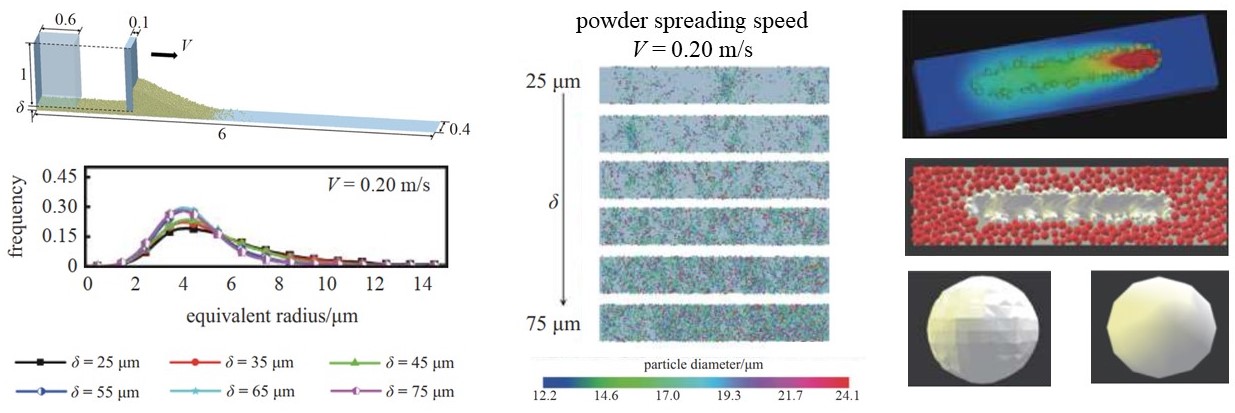

Numerical simulations of powder spreading process in selective laser melting and powder layer characterization. (pdf, doi)

Chin. J. Theor. Appl. Mech. 55, 1921–1938 (2023). (in Chinese) by H. L. Liu et al.

This study develops a discrete element modeling (DEM) framework to optimize powder spreading in selective laser melting (SLM) for tungsten particles. The rolling friction coefficient and surface energy density are determined by comparing experimental and simulation results, revealing their effects on particle flowability. Single-layer simulations identify optimal layer thickness and spreading speed for uniform, dense powder layers. A novel multi-layer DEM model improves efficiency and accuracy by representing unfused particles as movable spheres and capturing rough surfaces, providing insights to enhance powder bed uniformity and SLM reliability.

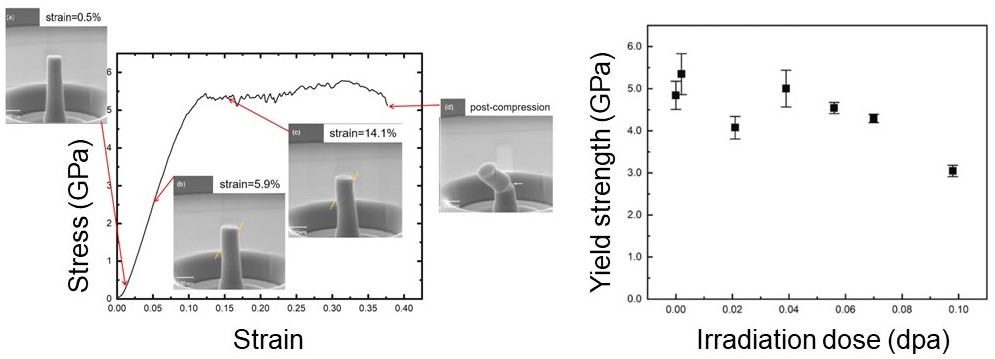

Ion irradiation induced softening in Cr2AlC MAX phase. (pdf, doi)

J. Alloys Compd. 939, 168660 (2023). by S. Y. Peng et al.

This study examines the mechanical behavior of Cr2AlC MAX phase under ion irradiation (0.002–0.098 dpa). Micropillar tests reveal yield strength and Young's modulus softening with increasing doses. Raman spectroscopy identifies irradiation-induced vacancies, indicating Cr2AlC's excellent irradiation resistance on structural stability. DFT calculations link the modulus reduction to these vacancies. Cr2AlC exhibits unique irradiation-induced softening, demonstrating superior tolerance.

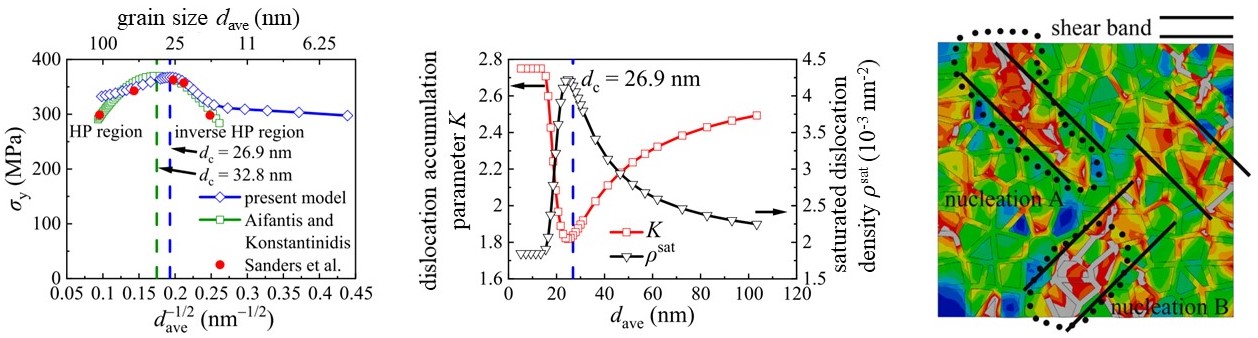

Overcoming strength–ductility trade-off of nanocrystalline metals by engineering grain boundary, texture, and gradient microstructure. (pdf, doi)

J. Mech. Phys. Solids 173, 105200 (2023). by Q. F. Han et al.

Crystal plasticity simulations show that the strength–ductility trade-off in nanocrystalline metals is governed by grain boundary (GB) damage and intragranular dislocation hardening. Strengthening GBs reduces damage and enhances dislocation hardening, alleviating the trade-off. Texture engineering promotes dislocation multiplication, delays shear bands, and prevents necking, effectively improving strength and ductility when combined with GB strengthening and grain refinement. Gradient nanocrystalline metals with smaller interior grains and larger surface grains exhibit superior failure resistance by limiting inner shear band damage. The existence of a most brittle grain size is confirmed.

High pressure-induced elimination of grain size softening in nanocrystalline metals: Grain boundary strengthening overwhelming reduction of intragranular dislocation storage ability. (pdf, doi)

Int. J. Plast. 153, 103261 (2022). by Q. F. Han and X. Yi

We explore the hydrostatic pressure-induced elimination of inverse Hall–Petch (HP) behavior in nanocrystalline metals through simulations incorporating a pressure- and size-dependent dislocation storage model. Hydrostatic pressure strengthens grain boundaries (GBs) and reduces intragranular dislocation storage, with GB strengthening dominating at smaller grain sizes. This eliminates the inverse HP effect, enhances tension–compression asymmetry, and suppresses strain localization.

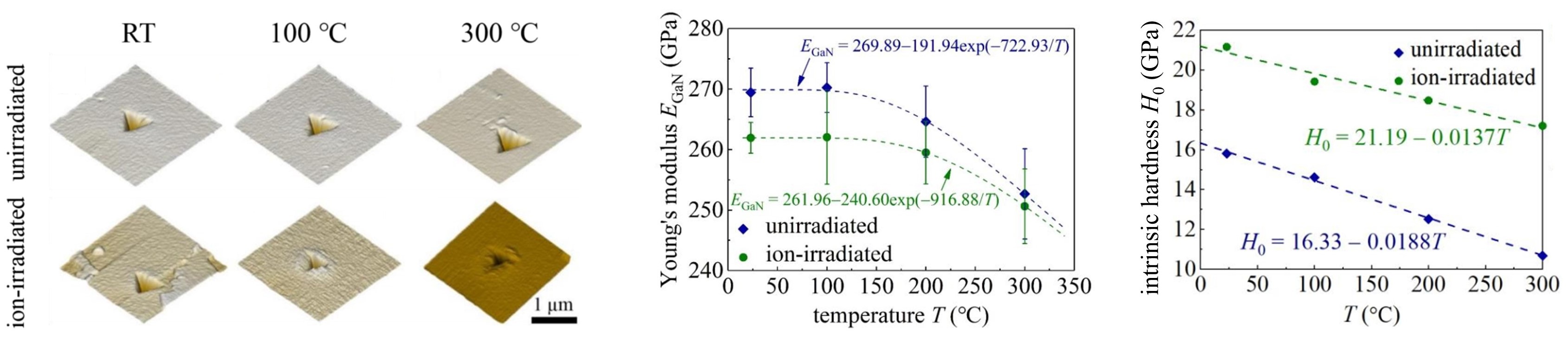

Effects of ion irradiation and temperature on mechanical properties of GaN single crystals under nanoindentation. (pdf, doi)

Materials 16, 7537 (2023). by Z. H. Dong et al.

Mechanical properties of GaN single crystals upon C ion irradiation: Nanoindentation analysis. (pdf, doi)

Materials 15, 1210 (2022). by Z. H. Dong et al.

Nanoindentation experiments reveal that C ion irradiation and temperature significantly influence the mechanical properties of GaN single crystals. The critical indentation load for pop-in events decreases with temperature but increases with irradiation, indicating defect-induced suppression of dislocation activity. Hardness exhibits an indentation size effect, while Young's modulus remains unchanged. Macroscopic hardness decreases with temperature due to reduced Peierls stress but increases with irradiation as defects pin dislocations.

New heat source model for accurate estimation of laser energy absorption near free surface in selective laser melting. (pdf, doi)

Extreme Mech. Lett. 56, 101894 (2022). by H. L. Liu et al.

This study develops a new heat source model for selective laser melting (SLM) that incorporates laser penetration and ray tracing to accurately simulate energy absorption. This approach effectively captures laser absorption behavior, even for propagation lengths smaller than the penetration depth, avoiding unphysically high temperature peaks. The model also smooths the recoil pressure profile, reduces the likelihood of extreme temperatures, and accurately simulates the melt pool temperature field, including cases with infinitesimally small liquid volume fractions.

Laser additive manufacturing of cracking-resistant superalloys. (pdf, doi)

Aeronautical Sci. Technol. 33, 26–42 (2022). (in Chinese) by H. Y. Wan et al.

This review explores the mechanisms behind typical cracking behaviors in laser additive manufacturing (LAM) superalloys, including liquation, solidification, and solid-state cracking, while systematically introducing cracking-resistant strategies. It also highlights recent trends and future research directions aimed at addressing these challenges.

Mechanical and microstructural characterization of additive manufactured Inconel 718 alloy by selective laser melting and laser metal deposition. (pdf, doi)

J. Iron Steel Res. Int. 29, 1322–1333 (2022). by F. Y. Lu et al.

In the as-built state, laser metal deposition (LMD) specimens exhibit lower yield strength and elongation due to a coarser microstructure caused by a cooling rate 2–3 orders lower than that of selective laser melting (SLM). After identical heat treatment, both processes significantly enhance yield strength, with LMD specimens achieving superior strength–ductility synergy. This improvement is attributed to small granular Laves phases and uniformly distributed nanoscale γ'' strengthening phases.

Selective electron beam melting (SEBM) of pure tungsten: Metallurgical defects, microstructure, texture and mechanical properties. (pdf, doi)

Materials 15, 1172 (2022). by X. Ren et al.

Effects of processing parameters on the densification, microstructures and mechanical properties of pure tungsten fabricated by optimized selective laser melting: From single and multiple scan tracks to bulk parts. (pdf, doi)

Int. J. Refract. Met. Hard Mater. 96, 105490 (2021). by X. Ren et al.

We fabricate pure tungsten via selective laser melting (SLM) and selective electron beam melting (SEBM). In SLM, an optimized processing window achieves bulk samples with a maximum relative density of 98.51% and an ultimate compressive strength of 1.007 GPa. In SEBM, bulk samples reach a higher relative density of 98.93% and compressive strength of 1.76 GPa. Microstructure, defects, and mechanical properties are characterized.

Computational study of evolution and fatigue dispersity of microstructures by additive manufacturing. (pdf, doi)

Chin. J. Theor. Appl. Mech. 53, 3263–3273 (2021). (in Chinese) by M. Yi et al.

Integrating the discrete element method, phase-field simulation, crystal plasticity finite element method, and extreme value statistics, a computational framework is developed to study the effects of laser scanning velocity in selective laser melting of 316L stainless steel. The framework effectively captures powder spreading, microstructure evolution, and anisotropic mechanical responses. Simulations reveal that higher scanning velocity reduces yield stress and fatigue life due to increased fatigue indicator parameter extremum, despite reducing fatigue dispersity.

A unified mechanistic model for Hall–Petch and inverse Hall–Petch relations of nanocrystalline metals based on intragranular dislocation storage. (pdf, doi)

J. Mech. Phys. Solids 154, 104530 (2021). by Q. F. Han and X. Yi

A unified size-dependent model for nanocrystalline metals predicts the Hall–Petch (HP) to inverse HP transition, incorporating grain-size effects on intragranular dislocation storage. Decreasing grain size in the inverse HP region harmonizes grain boundary and interior plasticity, enhancing both strength and ductility. Local shear bands form due to grain texture and resistant grains, with fracture surfaces exhibiting dimples spanning grains. Strengthening grain boundaries increases dislocation generation, raising yield strength and delaying inverse HP behavior.

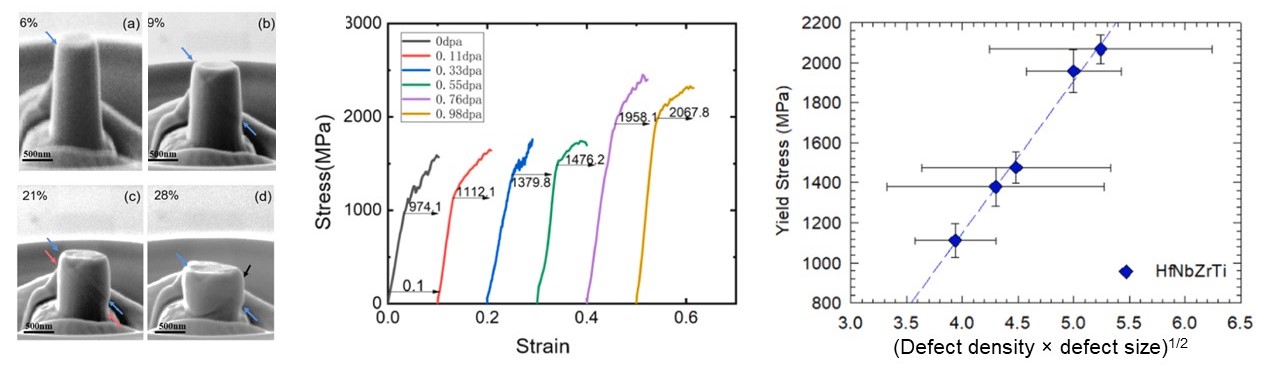

Mechanical behavior of the HfNbZrTi high entropy alloy after ion irradiation based on micro-pillar compression tests. (pdf, doi)

J. Alloys Compd. 892, 162043 (2021). by S. Y. Peng et al.

Irradiation-induced strengthening is attributed to dislocation loops, with yield strength increasing linearly from 974 MPa to 2068 MPa as dose increases up to 0.98 dpa. The defect density rises while loop size remains nearly constant. The delayed saturation of strengthening is linked to suppressed defect cluster aggregation. Compared to conventional alloys, HfNbZrTi exhibits minimal irradiation-induced strengthening, highlighting its excellent irradiation resistance and stability in mechanical properties.

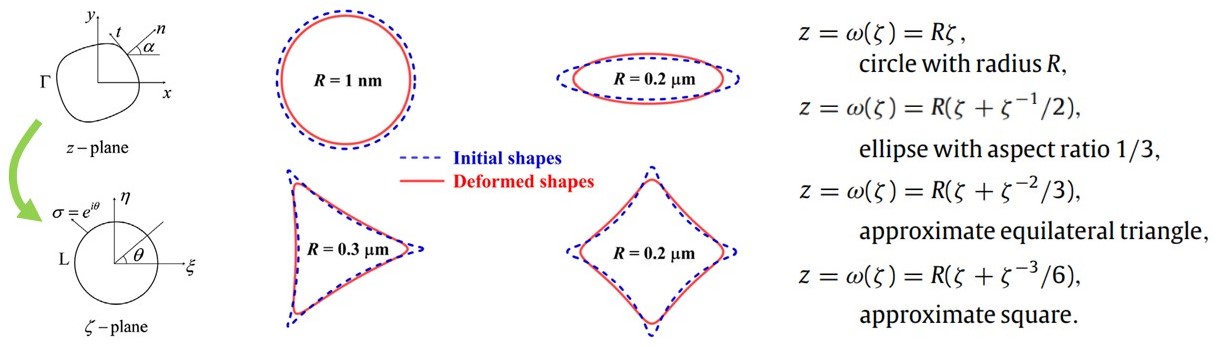

Morphological changes of nanofiber cross-sections due to surface tension. (pdf, doi)

Extreme Mech. Lett. 44, 101211 (2021). by S. Wang et al.

Using complex variable formulation, we investigate the morphological changes of soft nanofibers under surface tension within the framework of linear elasticity. We analyze nanofibers with circular, elliptical, triangular, and square cross-sections. Circular cross-sections consistently shrink, reducing both the radius and area, while non-circular cross-sections tend to round out, with their areas potentially increasing below critical sizes. The displacement at the cross-section boundary is linearly dependent on surface tension and independent of cross-section size.

Bulging and budding of lipid droplets from symmetric and asymmetric membranes: competition between membrane elastic energy and interfacial energy. (pdf, doi)

Soft Matter 17, 5319–5328 (2021). by M. Wang and X. Yi

As interfacial energy between the droplet and monolayer increases, droplets transition from a lens-like shape to a spherical bud, driven by energy minimization. This transition features a sharp change in interfacial contact area and elastic energy. Positive spontaneous curvature and asymmetries in bending rigidity or tension promote budding and influence its direction. Budding phase diagrams reveal conditions for budding size under symmetric and asymmetric scenarios.

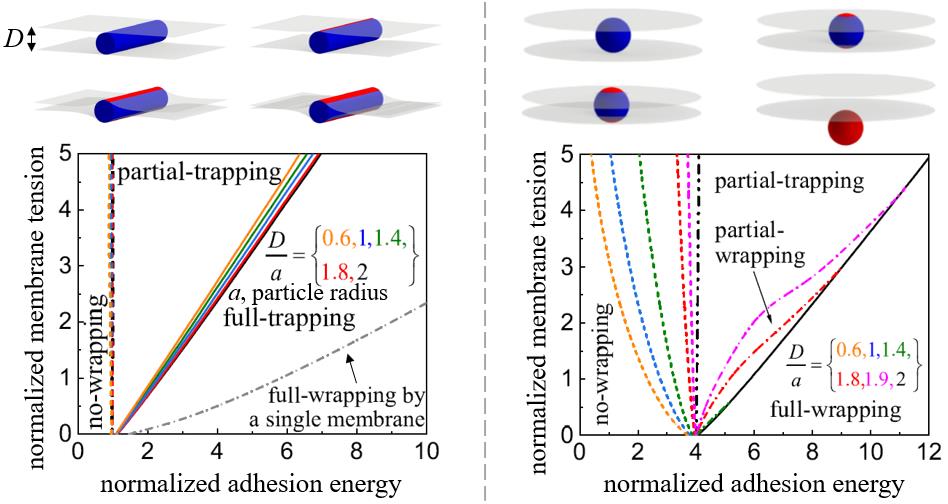

Mechanics of cell interaction with intercellular nanoparticles: Shape-dependent competition between two-membrane trapping and single-membrane wrapping. (pdf, doi)

Extreme Mech. Lett. 46, 101296 (2021). by Z. M. Wu and X. Yi

Membrane-mediated interaction of intercellular cylindrical nanoparticles. (pdf, doi)

Phys. Rev. E 104, 034403 (2021). by Z. M. Wu and X. Yi

We investigate mechanical behaviors of cylindrical and spherical nanoparticles confined between two cell membranes, revealing two interaction modes: two-membrane trapping and single-membrane wrapping. Cylindrical nanoparticles favor trapping between membranes, while spherical nanoparticles are more prone to wrapping and engulfment, giving cylindrical particles a greater likelihood of penetrating solid tumors. The trapping and wrapping behaviors are influenced by membrane tension, bending rigidity, adhesion energy, and intermembrane distance. In addition, multiple cylindrical nanoparticles exhibit no cooperative trapping.

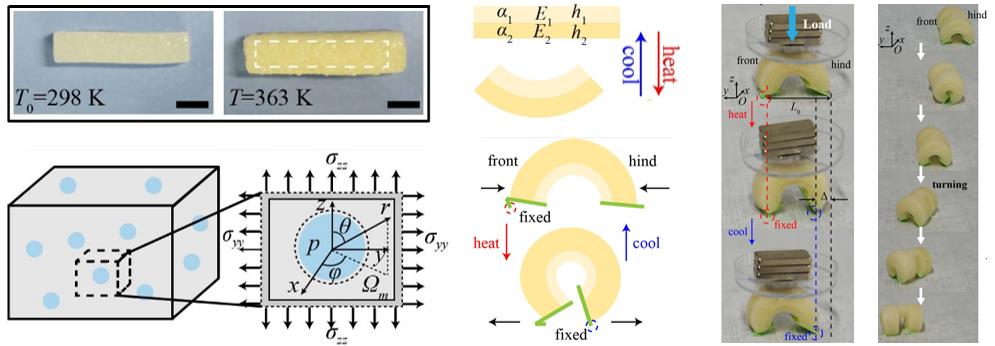

Soft actuators based on liquid–vapor phase change composites. (pdf, doi)

Soft Robotics 8, 251–261 (2021). by X. Y. Li et al.

Design, fabrication and mechanical properties of soft composites with liquid inclusions. (pdf, doi)

Acta Mater. Comp. Sin. 38, 1–15 (2021). (in Chinese) by X. Y. Li et al.

This study uses micromechanical theory to explore the effective thermomechanical properties of phase-change material (PCM)-elastomer composites, demonstrating how vapor pressure in PCM inclusions enhances composite expansion and output stress. By controlling the distribution and content of inclusions, programmable bilayer structures are fabricated, enabling complex locomotion and adaptable gripping through assemblies of deformable cells with asymmetric friction and deformation.

Our review (in Chinese) highlights recent advances in their functional design, fabrication methods, effective mechanical properties, and size-dependent behaviors. It also addresses current challenges and key issues requiring further attention.